Passion for surface treatment

From the building of the most complex sandblasting machines to top services: sandblasting, shot peening, metallizing, powder coating, dry ice cleaning and laser surface treatment.

Passion for surface treatment

From the building of the most demanding sandblasting machines to top services: sandblasting, shot peening, metallizing, powder coating, dry ice cleaning and laser surface treatment.

01

What do we do?

01

What do we do?

We are trusted by:

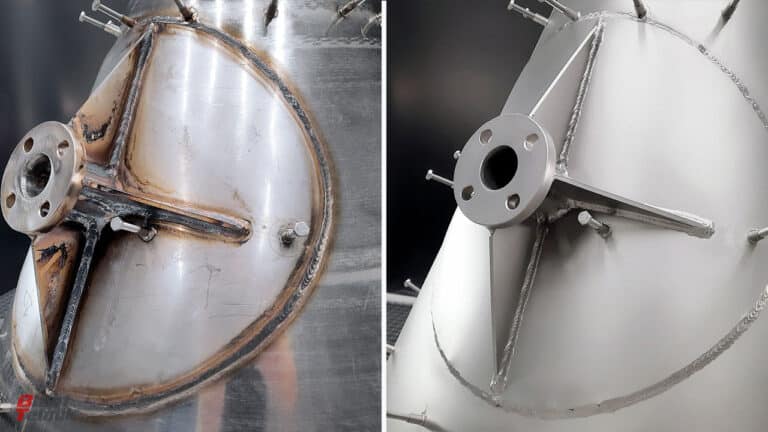

Shot peening

Increase the life of metal parts by as much as 1000x and improve the lubricating characteristics of elements with the best method for the strengthening of metals in the world – Shot Peening.

Dry ice

Sandblasting

Metallizing

Improve the resistance of materials to corrosion, wear and weathering and at the same time improve the look and functionality of the final product.

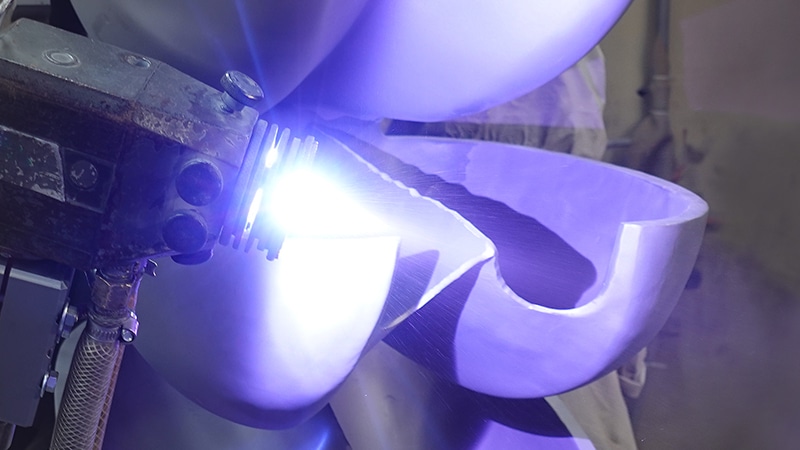

Laser

Ensure less downtime in your production with an accurate, efficient, clean, fast, easy and quiet method for maintaining machines and tools – the laser.

Finishing and rubber coating

Protect materials from the external environment and at the same time improve their aesthetic appearance and increase their sales value with powder coating or wet painting.

Shot peening

Increase the life of metals by as much as 1000x and improve the lubricating characteristics of elements with the best method for the strenghtening of metals in the world, shot peening.

Dry ice

Sandblasting

Metallizing

Improve the resistance of materials to corrosion, wear and weathering and at the same time improve the look and functionality of the final product.

Laser

Ensure less downtime in your production with an accurate, efficient, clean, fast, easy and quiet method for maintaining machines and tools – the laser.

Finishing

Protect materials from the external environment and at the same time improve their aesthetic appearance and increase their sales value with powder coating or wet painting.

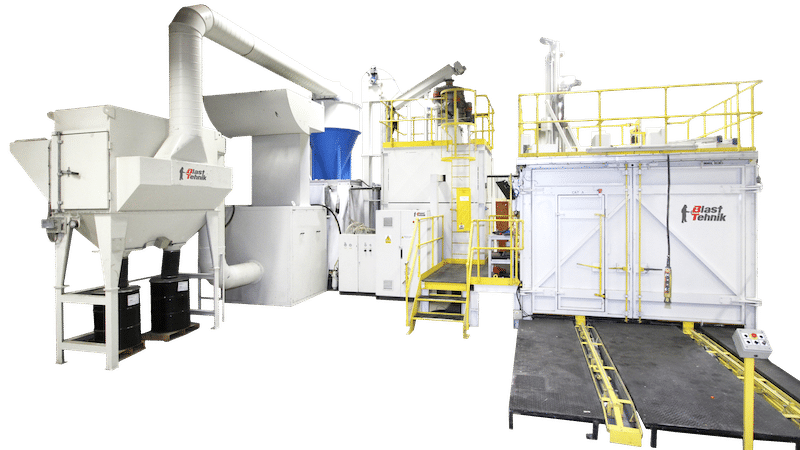

Improve the efficiency and ergonomics of your production processes with custom-made Blast Tehnik machines.

We develop and build dedicated surface treatment machines, filtration and separation systems and mobile lifts for all industries.

More than 40 years of experience

We are professional, competent and responsive, and we have our own production and development.

- An environmentally-friendly company

- Satisfied customers in 12 countries

- 1000 km service range

- Presence in all industries

- Emergency response available in less than 1 hour

YEAR WARRANTY

Customer testimonials

4 years have passed since the restoration. The coating in our polyurethane tanks is still flawless, which proves that all procedures were performed correctly and high-quality materials were used. We recognized Blast Tehnik as a trustworthy partner and also started collaborating in some other areas.

Igor Cokan

Production engineer

Johnson Controls Slovenj Gradec, d.o.o.

We have identified a trustworthy business partner in Blast Tehnik. With their surface treatment services we achieve excellent bonding results with composite profiles. We especially appreciate their production capacities and precise process control, which helps us maintain good relationships with our demanding end customers.

Christian Steiner

Sales

Excel Composites

Through our presence in all industries we are working with international corporations and scientific research establishments and institutes.

We are a company with a staff of 15 carrying out our mission in the following industries: automotive, aerospace, pharmaceutical, medical, defence and others.

We complement our core service activity with services and sandblasting for the smaller customers.

Founder and CEO

I am convinced that we can meet the needs of our customers best if the company management also takes the tools in our hands every once in a while!

I therefore encourage all employees to join me in the field, where we study the specifics of individual industries together with the experts.

- March 19, 2024

- Blasttehnik

- September 26, 2023

- Blasttehnik

- September 21, 2023

- Blasttehnik

- March 19, 2024

- Blasttehnik

- September 26, 2023

- Blasttehnik