We were contracted in 2019 for internal blasting on 100 meters of pipeline (1 meter in diameter) according to the demanding standards for automatic blasting in the nuclear industry, and delivered with flying colours. Intensive preparations are currently underway for the 2021 overhaul, where we are repeating the procedure on the rest of the pipeline.

Based on our past experience in the most demanding industries, we also perform automatic pipeline blasting in the chemical and pharmaceutical industries, as well as in hydropower and thermal power plants in Slovenia and abroad.

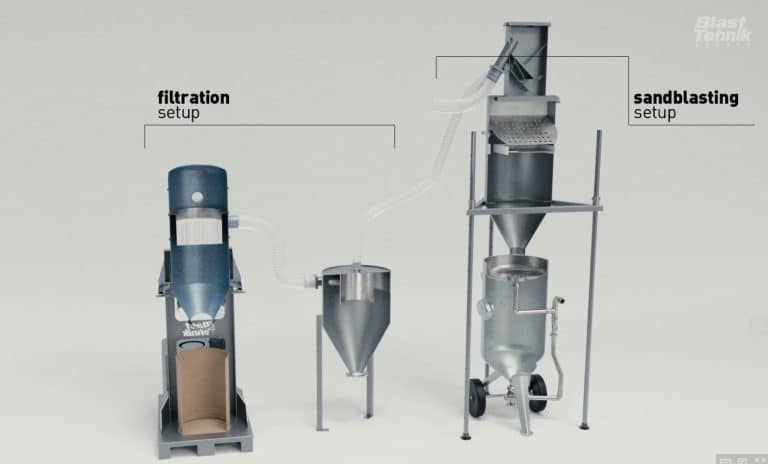

We offer our customers a premium comprehensive service using dedicated automated blast machines, and our in-house laboratory for the development and testing of surface treatments.

We would like to thank our customer Westinghouse Electric Company and the Krško Nuclear Power Plant, who recognized a professional partner in us and once again entrusted us with a demanding task.