Increase the resistance of your hi-tech elements to dynamic loads and extend their service life by as much as 1000x.

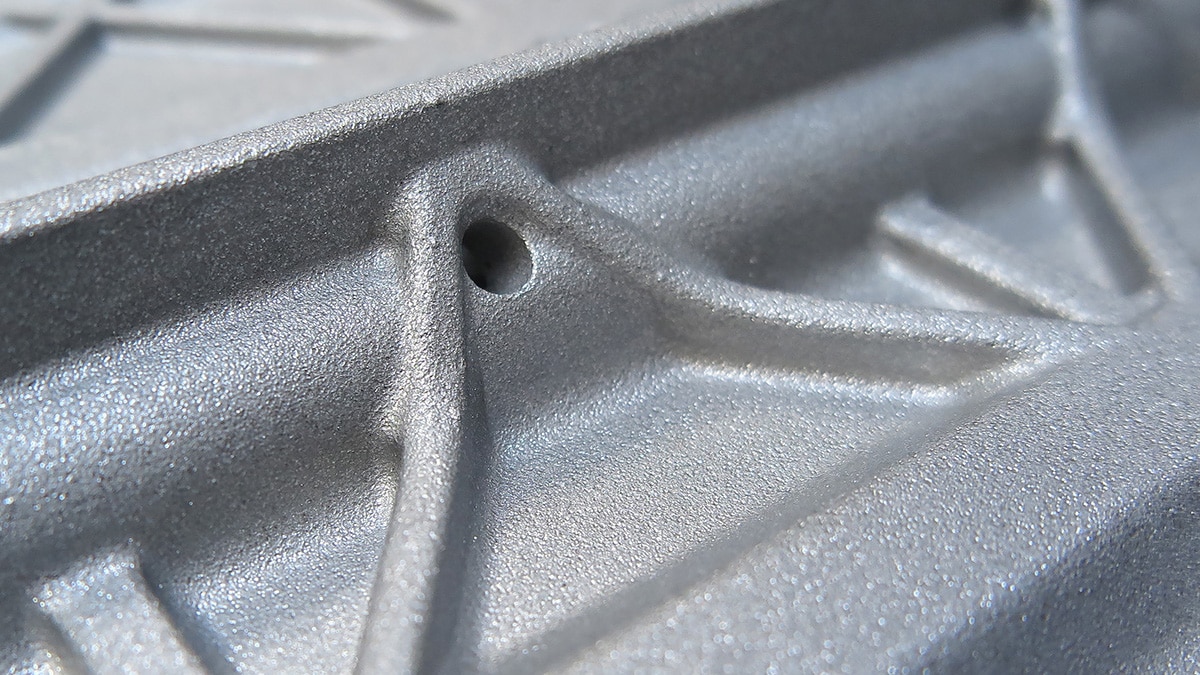

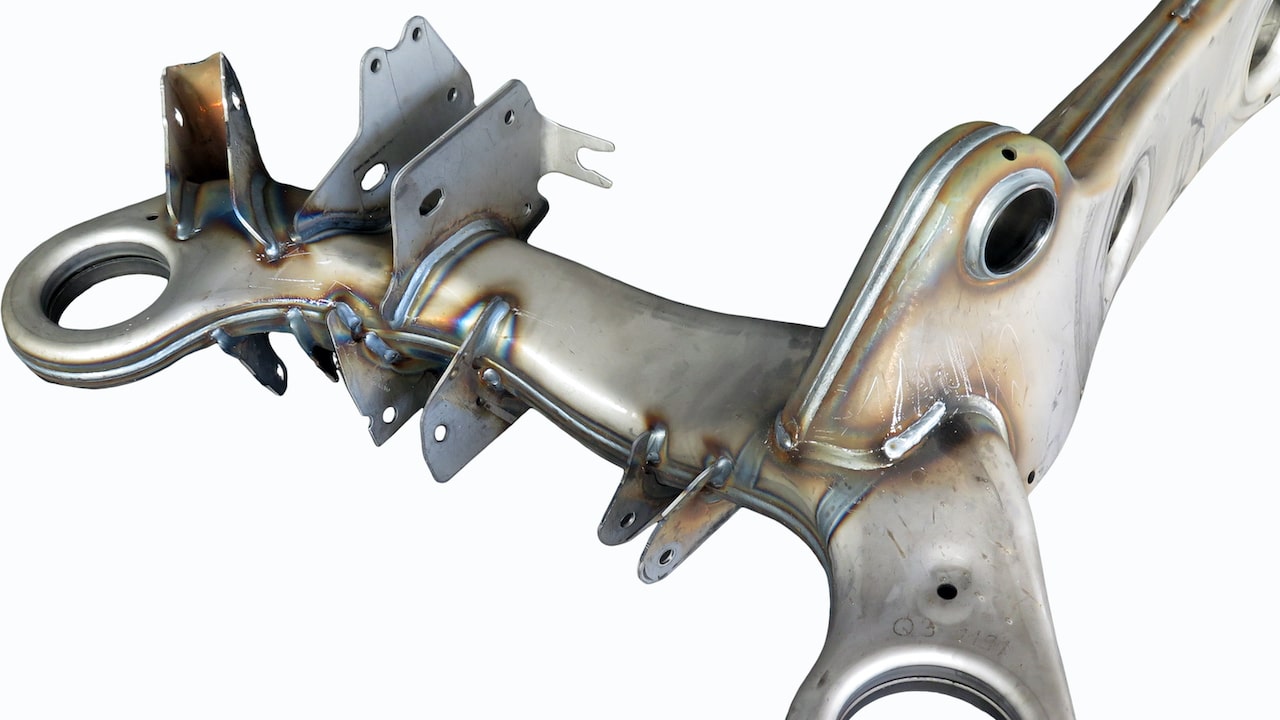

Shot peening reduces the possibility of failure of key safety components after welding or machining.

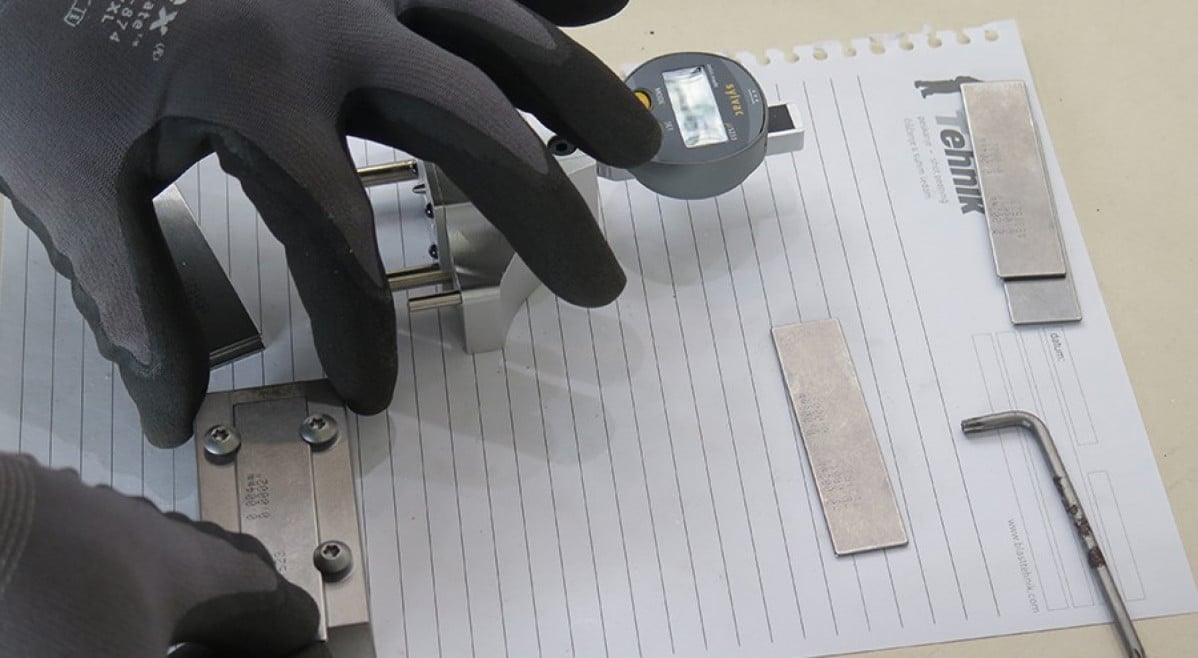

We provide greater strength, longer service life and 100% process repeatability.

When it comes to adding strength and improving the durability of metals, there is no better technique in the world than shot peening.

In 1982, NASA began using it to strengthen rocket parts, and today it is the gold standard in the automotive, aerospace and other industries.

Shot peening is a modern version of the method used by the blacksmiths since ancient times to add strength to their products.

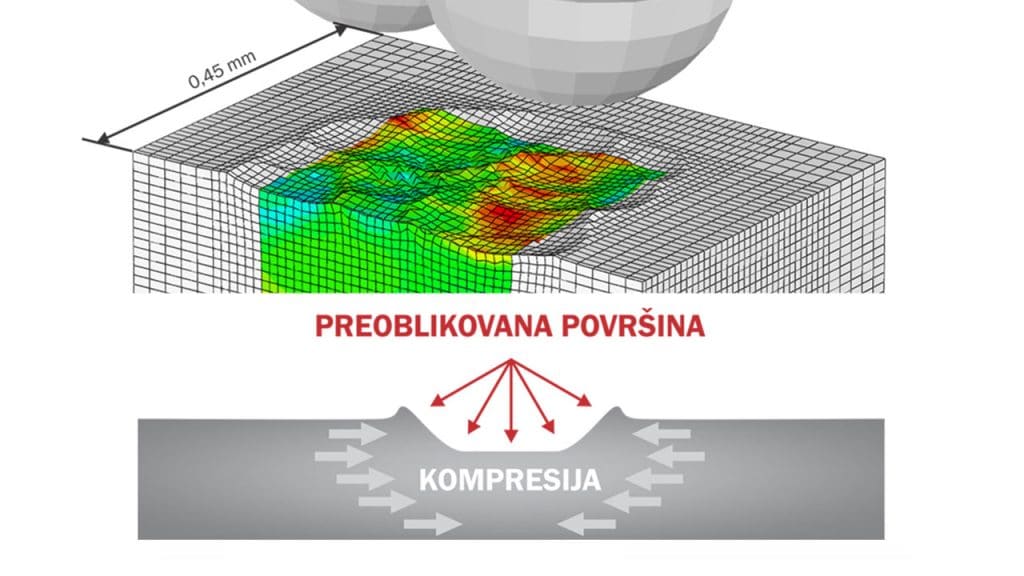

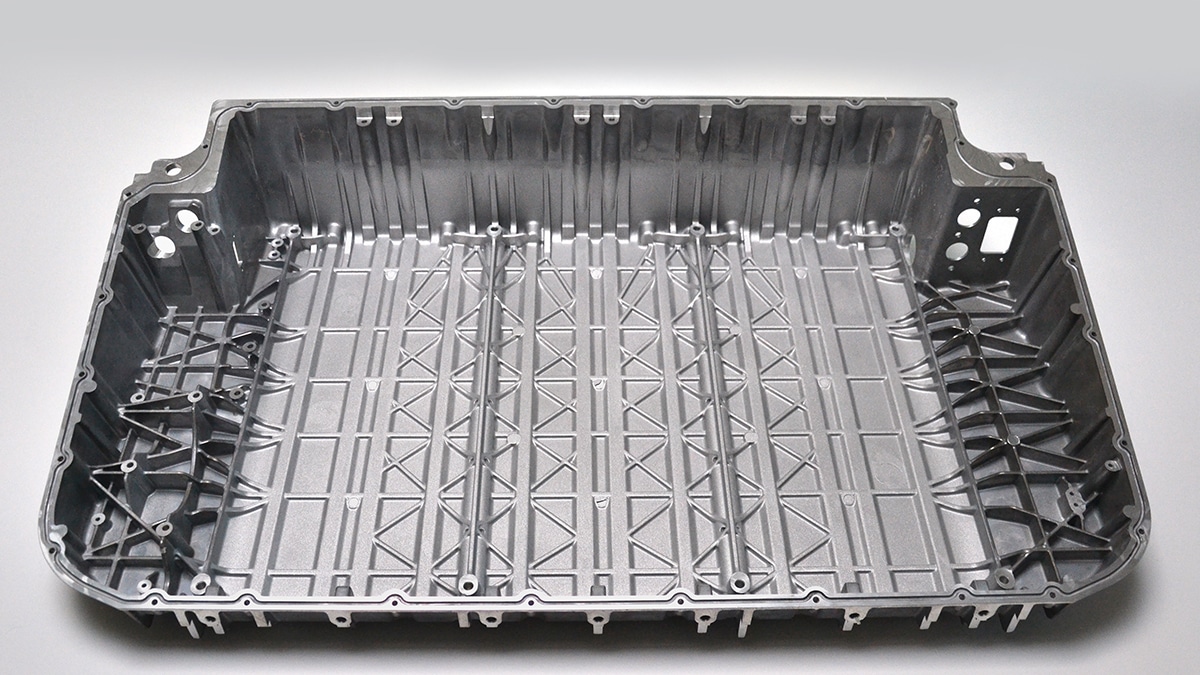

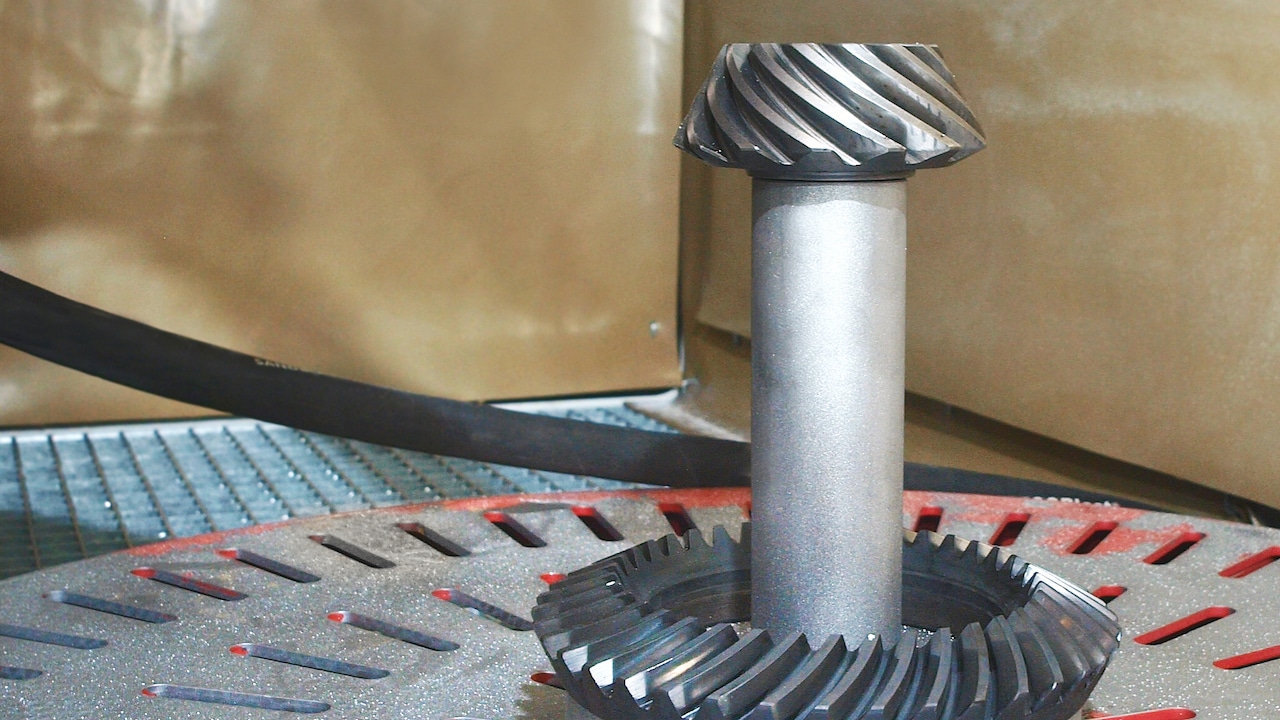

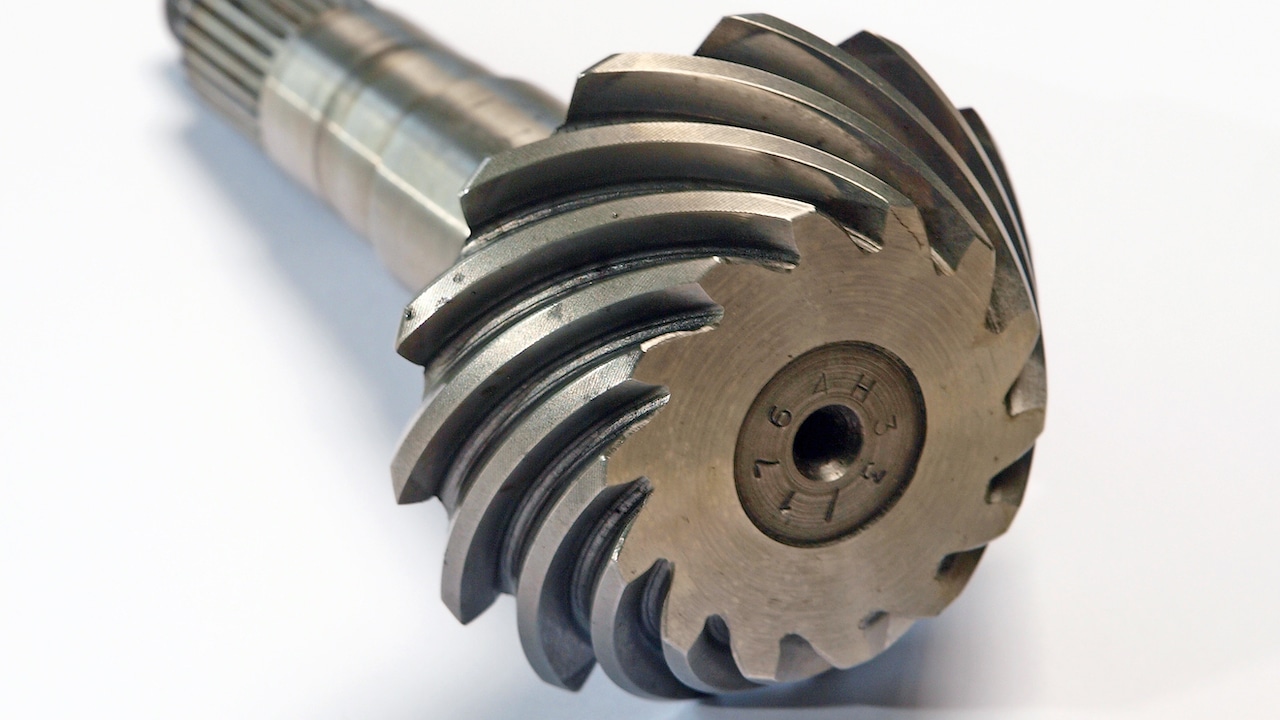

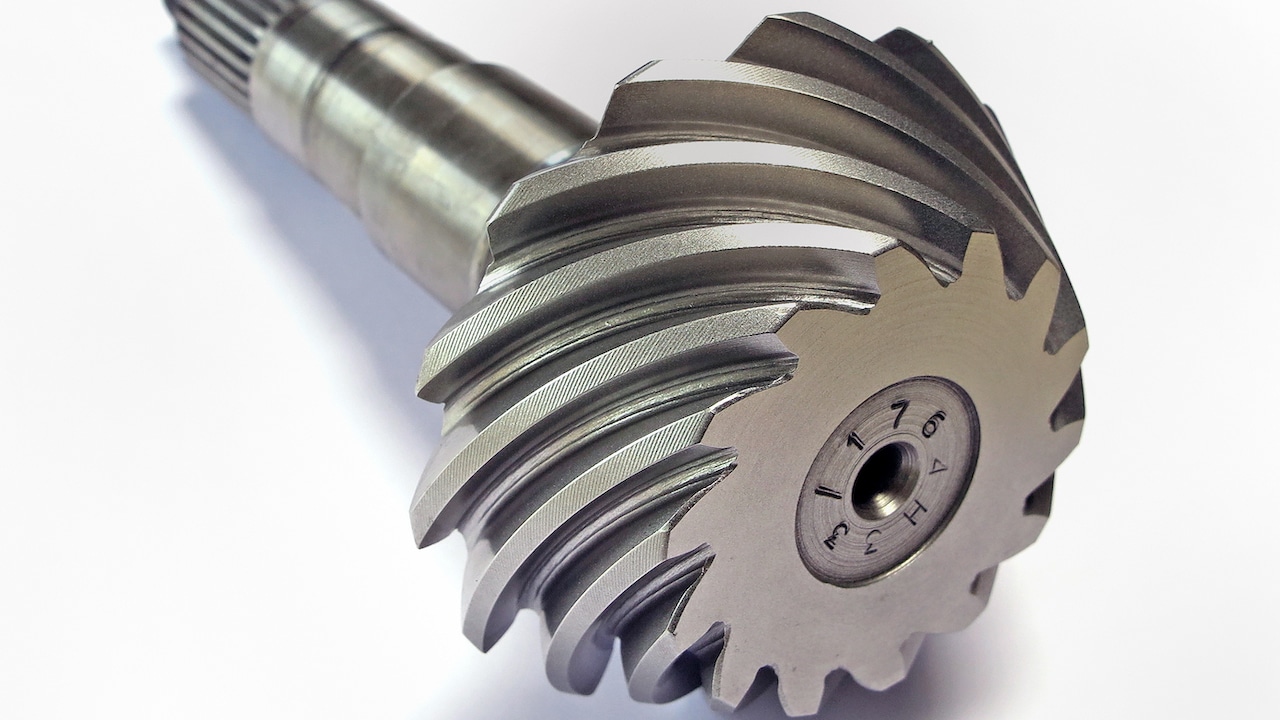

The shot – round in shape – acts as a micro hammer when striking the workpiece, creating small dents in the surface.

After a large number of impacts, these are smoothed into a flat, hard surface.

This creates a layer of compressive residual stresses, which virtually eliminates the possibility of failure of workpiece structure.

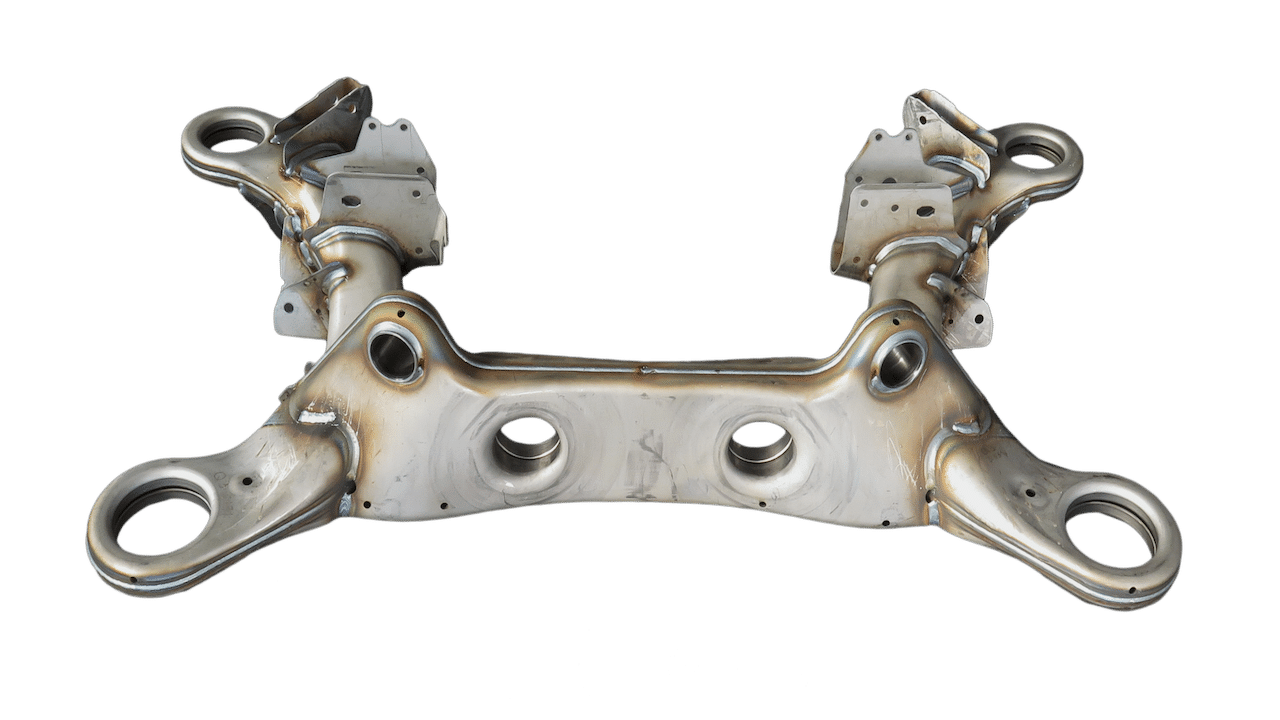

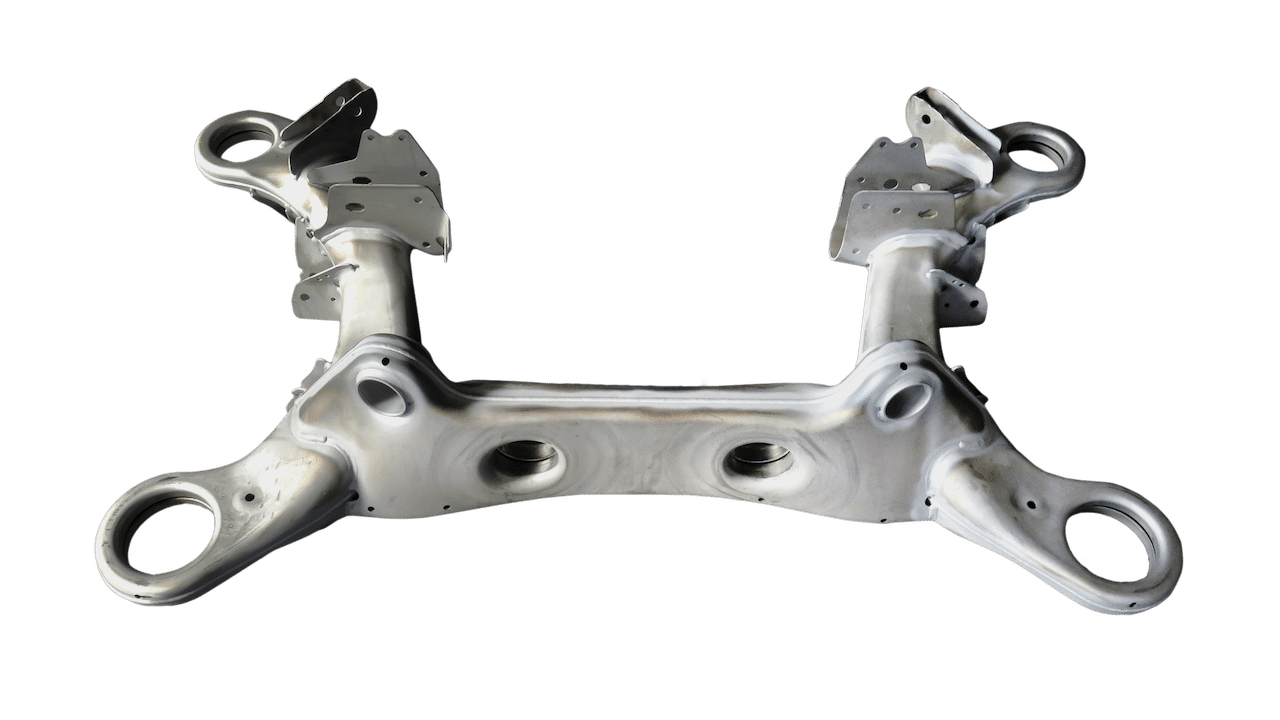

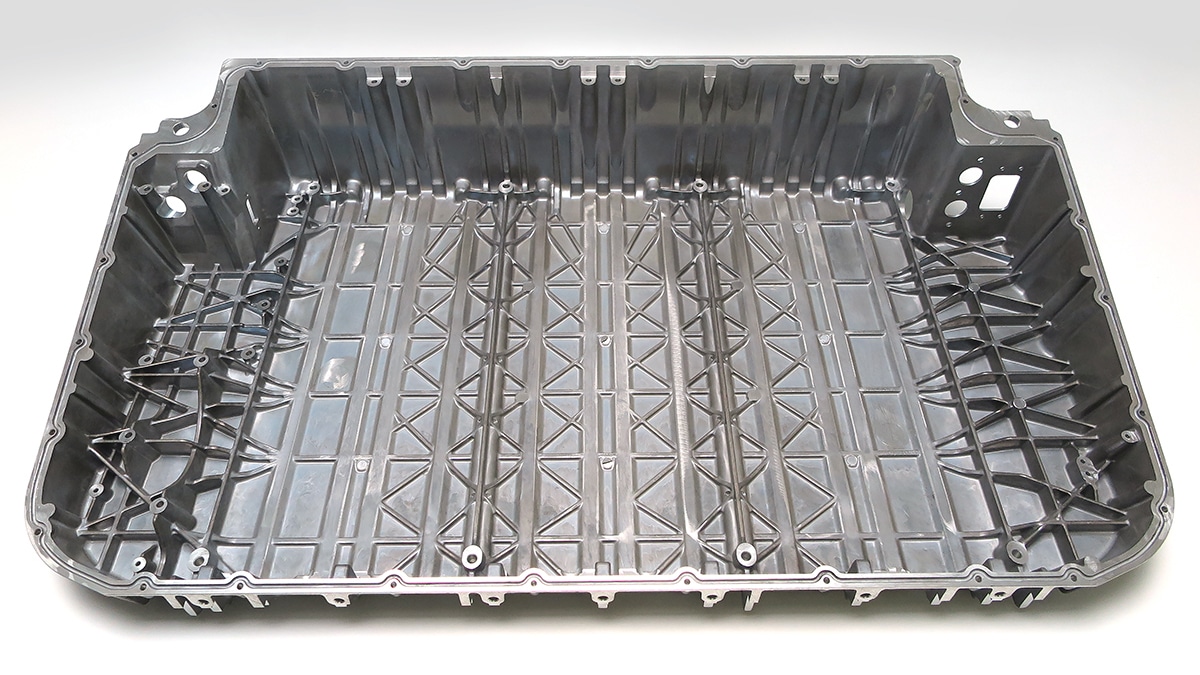

Shot peening is used to strengthen crankshafts, connecting rods, gears, various types of springs and turbine blades, wing elements, aircraft landing gears, safety screws and much more.

Click on an industry below for specific case studies.

Use cases:

Use cases:

Use cases:

Use cases:

Use cases:

“The renovation of key safety points on passenger aircraft is a big responsibility. It is part of the general aircraft refurbishment, which involves only certified contractors. Blast Tehnik fully meets our requirements and expectations, and we can say that flying is safer after Blast Tehnik processes the parts.”

Head of Engineering

Adria Tehnika d.d.

From the production of the most demanding sandblasting machines to the implementation of top-quality sandblasting services.

LOOKING FOR A SHOT PEENING MACHINE?